Cast Iron Single Stage Centrifugal Pump Manufacturer – S, SH Single-Stage Double-Suction Centrifugal Pump – State Machinery Equipment Manufacturing

Cast Iron Single Stage Centrifugal Pump Manufacturer – S, SH Single-Stage Double-Suction Centrifugal Pump – State Machinery Equipment Manufacturing Detail:

Structural features

1. Compact structure, beautiful appearance, good stability and easy installation.

2. Stable operation The optimally designed double-suction impeller reduces the axial force to a minimum, and the blade shape with excellent hydraulic performance, the inner surface of the centrifugal pump casing and the surface of the impeller have anti-cavitation performance.

3. SKF and NSK bearings are selected for bearings to ensure smooth operation, low noise and long service life.

4. The shaft seal shall be mechanical seal or packing seal. It can guarantee 8000 hours of operation without leakage.

5. The installation form of centrifugal pump does not need to be adjusted during assembly, and it can be used according to the on-site conditions. Discrete or horizontal installation.

6. The installation of self-priming device can realize automatic water absorption, that is, no need to install bottom valve, no vacuum pump, no need to pour back, and the centrifugal pump can be started.

Features

The suction port and discharge port of this type of pump are below the axis line of the pump, and the axis is perpendicular to the horizontal direction. There is no need to disassemble the inlet and outlet water pipes and the motor during maintenance. Viewed from the direction of rotation, the pump rotates clockwise/according to the user If necessary, it can also be changed to rotate counterclockwise.

The main parts of the pump are: pump body, pump cover, impeller, shaft, double suction sealing ring, shaft sleeve, etc.

The pump body and the pump cover constitute the working chamber of the impeller, and the pipe screw holes for installing the vacuum gauge and the pressure gauge are made on the inlet and outlet flanges. The lower part of the water inlet and outlet flanges is provided with pipe screw holes for water discharge.

The impeller that has been checked for static balance is fixed on the shaft with the bushing nuts on both sides of the bushing, and its axial position can be adjusted by the bushing nuts.

The pump shaft is supported by two single row radial ball bearings. The bearings are installed in the bearing body, installed at both ends of the pump body, and lubricated with butter.

The double suction sealing ring is used to reduce the leakage of water from the pressure chamber of the pump back to the suction chamber.

The pump is directly driven by the electric motor through the elastic coupling. If necessary, it can also be driven by an internal combustion engine.

The shaft seal is a soft packing seal, and a mechanical seal structure can be used according to user needs.

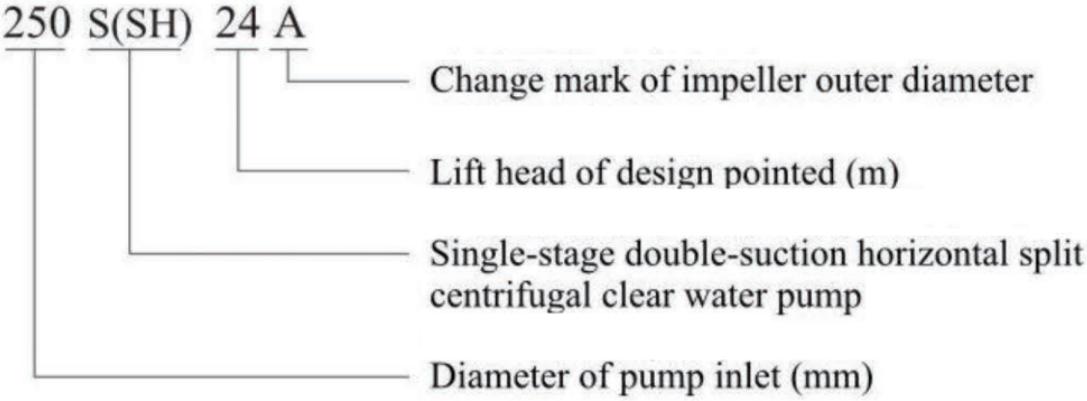

Type Designation

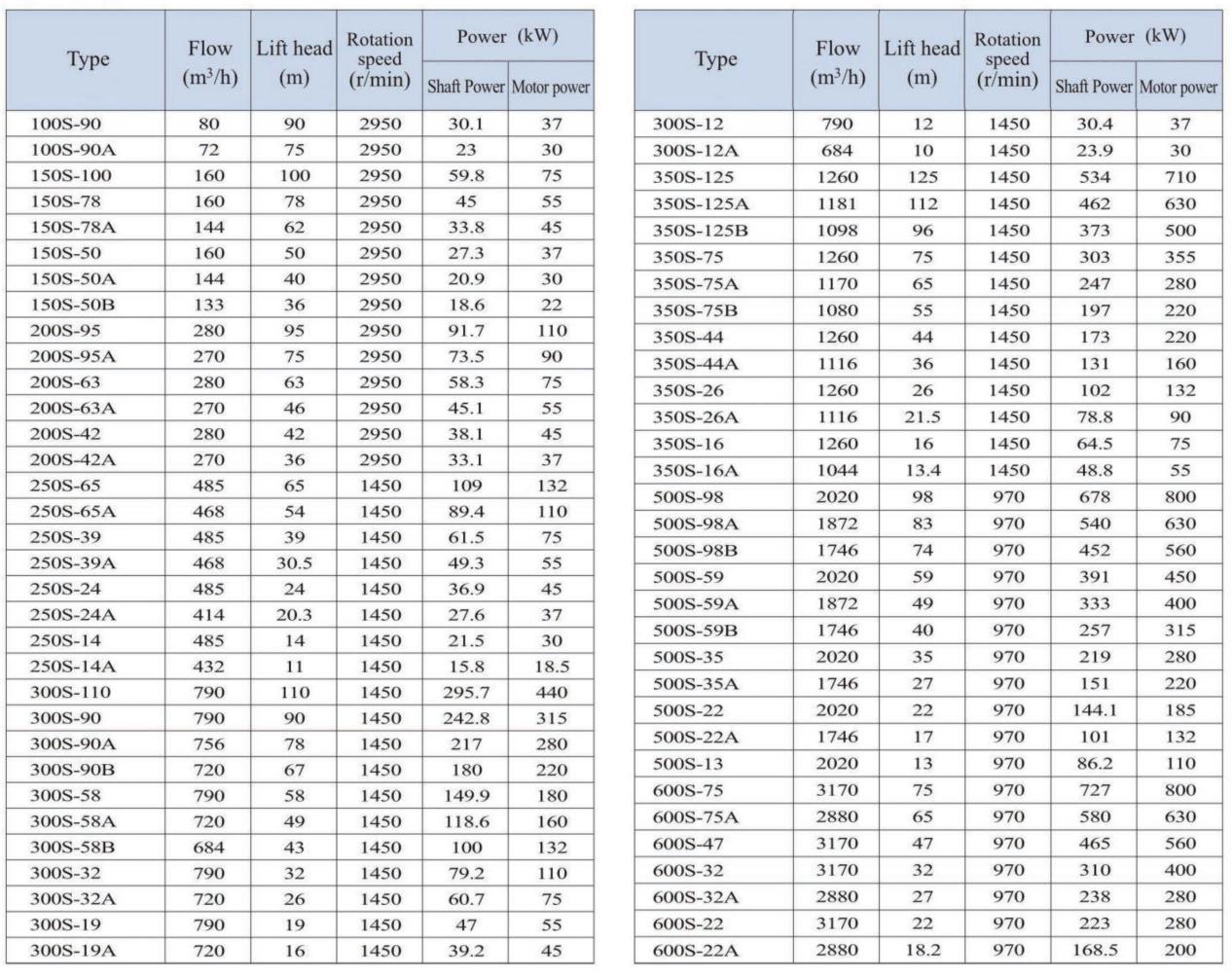

Performance Parameter

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Cast Iron Single Stage Centrifugal Pump Manufacturer – S, SH Single-Stage Double-Suction Centrifugal Pump – State Machinery Equipment Manufacturing , The product will supply to all over the world, such as: Poland, Johor, Sierra Leone, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!