Cast Iron Single Stage Single Suction Chemical Pump Manufacturer – SZ Series Water Ring Vacuum Pump – State Machinery Equipment Manufacturing

Cast Iron Single Stage Single Suction Chemical Pump Manufacturer – SZ Series Water Ring Vacuum Pump – State Machinery Equipment Manufacturing Detail:

Product Introduction

SZ series water ring type vacuum pumps and compressors are used to pump or compress air and other noncorrosive and water-insoluble gas not containing solid particles, SO as to form up vacuum and pressure within closed container. But the gas sucked in allows a little mixture of liquid, They are widely used. in the fields of machinery, petrochemical, pharmaceuticals,foodstuff, sugar production and electronics.

As in the process of operation, the compression of gas is isothermal,there is hardly any risk upon compressing and pumping inflammable and explosive gas, making them more widely accepted.

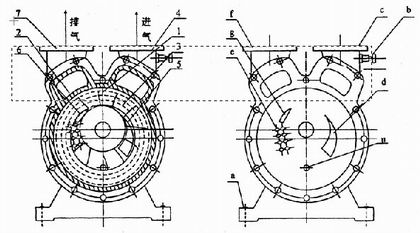

the working principle of SZ type water ring vacuum pump:

The SZ water ring vacuum pump is shown in Figure 1. The impeller ① is eccentrically installed in the pump body ②, and a certain height of water is injected into the pump when starting.

Therefore, when the vane wheel rotates, the water is affected by centrifugal force to form a rotating water ring on the pump body wall ③, the upper inner surface of the water ring is tangent to the hub, and rotates along the main direction of the arrow. During the first half-turn, the water ring The inner surface is gradually separated from the hub, so the SZ water ring vacuum pump forms a space between the impeller blades and gradually expands, so that air is sucked in at the suction port; in the process of the second half rotation, the inner surface of the water ring gradually approaches the hub, The volume of the space between the blades is reduced, and the air between the blades is compressed and discharged.

In this way, every time the impeller rotates, the space volume between the blades changes once, and the water between each blade reciprocates like a piston, and the SZ water ring vacuum pump continuously sucks gas.

Since the water will heat up during work, and part of the water will be discharged together with the gas, so the SZ water ring vacuum pump must be continuously supplied with cold water to cool and replenish the water consumed in the pump during operation. The supplied cold water is preferably 15°C.

When the gas discharged by the SZ water ring vacuum pump is exhaust gas, a water tank is connected to the exhaust end. After the exhaust gas and a part of the water it carries are discharged into the water tank, the gas runs away from the outlet pipe of the water tank, and the water falls into the water tank. The bottom is returned to the pump through the return pipe. If the circulation time is long, it will generate heat. At this time, a certain amount of cold water needs to be supplied from the water supply of the water tank.

Figure 1 Figure 2

1. Impeller 2. Pump body 3. Water ring 4. Intake pipe 5. Suction hole 6. Exhaust hole 7. Exhaust pipe a. Foot b. Vacuum adjustment valve c. Intake pipe d. Suction hole e. Rubber valve f. Exhaust pipe g. Exhaust hole u. Water inlet hole

Structure diagram of water ring vacuum pump and compressor

Since the water will heat up during work, and part of the water will be discharged together with the gas, so the SZ water ring vacuum pump must continuously supply cold water during operation to cool and supplement the water consumed in the pump.

When the gas discharged by the SZ water ring vacuum pump is exhaust gas, a water tank is connected to the exhaust end. After the waste water and a part of the water tank, the gas runs away from the outlet pipe of the water tank, and the water falls into the bottom of the water tank. The return pipe is returned to the pump for use. If the water circulates for a long time, it will generate heat. At this time, a certain amount of cold water needs to be supplied from the water supply of the water tank.

When the SZ water ring vacuum pump is used as a compressor, a gas-water separator should be connected to the exhaust end. When the gas with water enters the separator, it will be automatically separated, and the outlet of the gas mountain separator will be sent to the place where it is needed, while the hot water It is released through an automatic switch. (It is easy to heat up when the gas is compressed, and the water becomes hot water after it comes out of the pump), the SZ water ring vacuum pump should also continuously supply cold water at the bottom of the separator to supplement the discharged hot water, and at the same time play a cooling role .

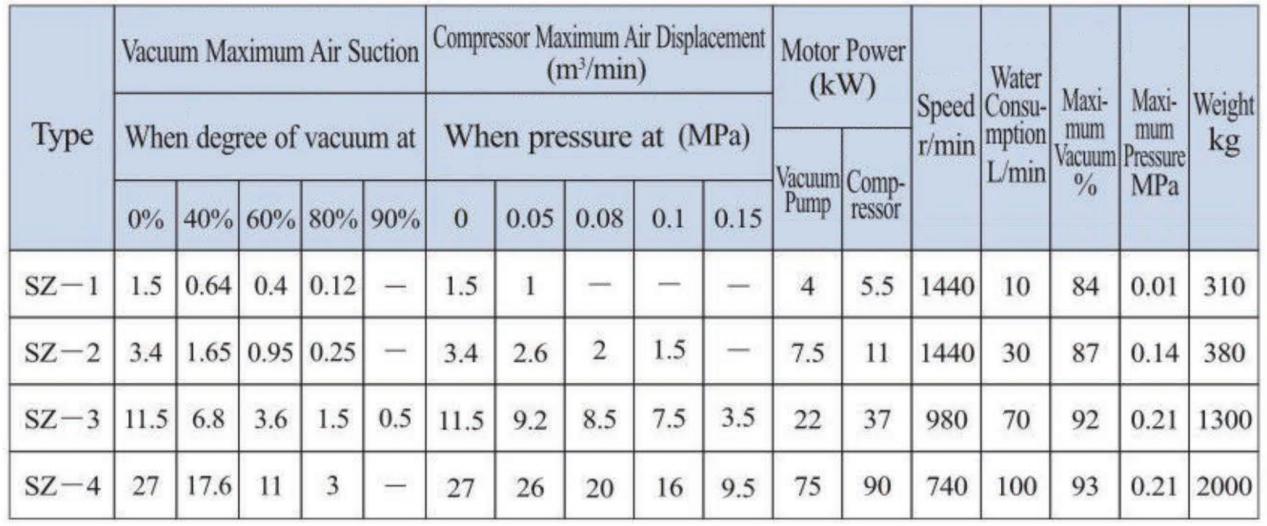

Performance Parameter

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Cast Iron Single Stage Single Suction Chemical Pump Manufacturer – SZ Series Water Ring Vacuum Pump – State Machinery Equipment Manufacturing , The product will supply to all over the world, such as: Iran, Manila, panama, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!