Cast Iron Stainless Steel Centrifugal Water Pump Manufacturer – KTB Refrigeration Air-Conditioner Pump – State Machinery Equipment Manufacturing

Cast Iron Stainless Steel Centrifugal Water Pump Manufacturer – KTB Refrigeration Air-Conditioner Pump – State Machinery Equipment Manufacturing Detail:

Product Application

KTB type pump is a single-stage single-suction centrifugal pump specially designed for air conditioning and refrigeration system

-Pumping hot and cold water for heat in and cooling system.

-Pressure boosting system.

-Hot and cold water cycle.

-Liquid transfer in industry, agriculture, horticulture,etc.

Type Designation

Product Characteristics

Dust-proof and splash-proof: protection class. IP54, a fully enclosed strueture, higher quality, and available for outdoor use.

The motor’s maximum working temperature is 20℃ higher than that of the common Y motors: Y2 motor and class F insulation, and the high-quality single-stage pump can still be used reliably at rated power even at 120℃.

The shaft seal’s service life is more than double longer: thanks to its new mechanical seal and forced circulation circulatory system, its operating environment is improved with zero leakage plus a life more than double longer than that of common mechanical seal of ordinary domestic water pumps.

More energy-saving: the Y2 motor is 2-4% more efficient; with a special structure, the impeller has an excellent hydraulic model, leading to smooth flowing and small losses, thus ensuring the pump’s optimal performance.

Quieter: the motor is directly connected and coaxial with the pump,leading to small vibration and low noise; the motor fin shape has a reasonable layout to reduce noise, while the high-quality bearings contribute to stable and quiet operation; and the large-diameter impeller, after strict dynamic balancing, contributes to less vibration.

Easier to use: thanks to its modular design and strong versatility of parts,it’s easy for dis-assembly; and the pump’s inlet and outlet have the same diameter while its body is supported by feet, thus resulting in stable and reliable operation.

Greatly space effective: with a unique mounting structure, it’s greatly space-effective and saves more than 40% of construction investment; and a low-power pump can be mounted on any position of the pipeline like a valve without any base plate, so it will not occupy any area of the pump room.

Less management costs: the entire shaft plus bearings with special structures and configuration, high-quality casting, with high dimensional precision and a nice look, a strong overload capacity of the Y2 motor and other characteristics can reduce the maintenance costs significantly, extend the pump’s life greatly and save management expenses by 50%-70%.

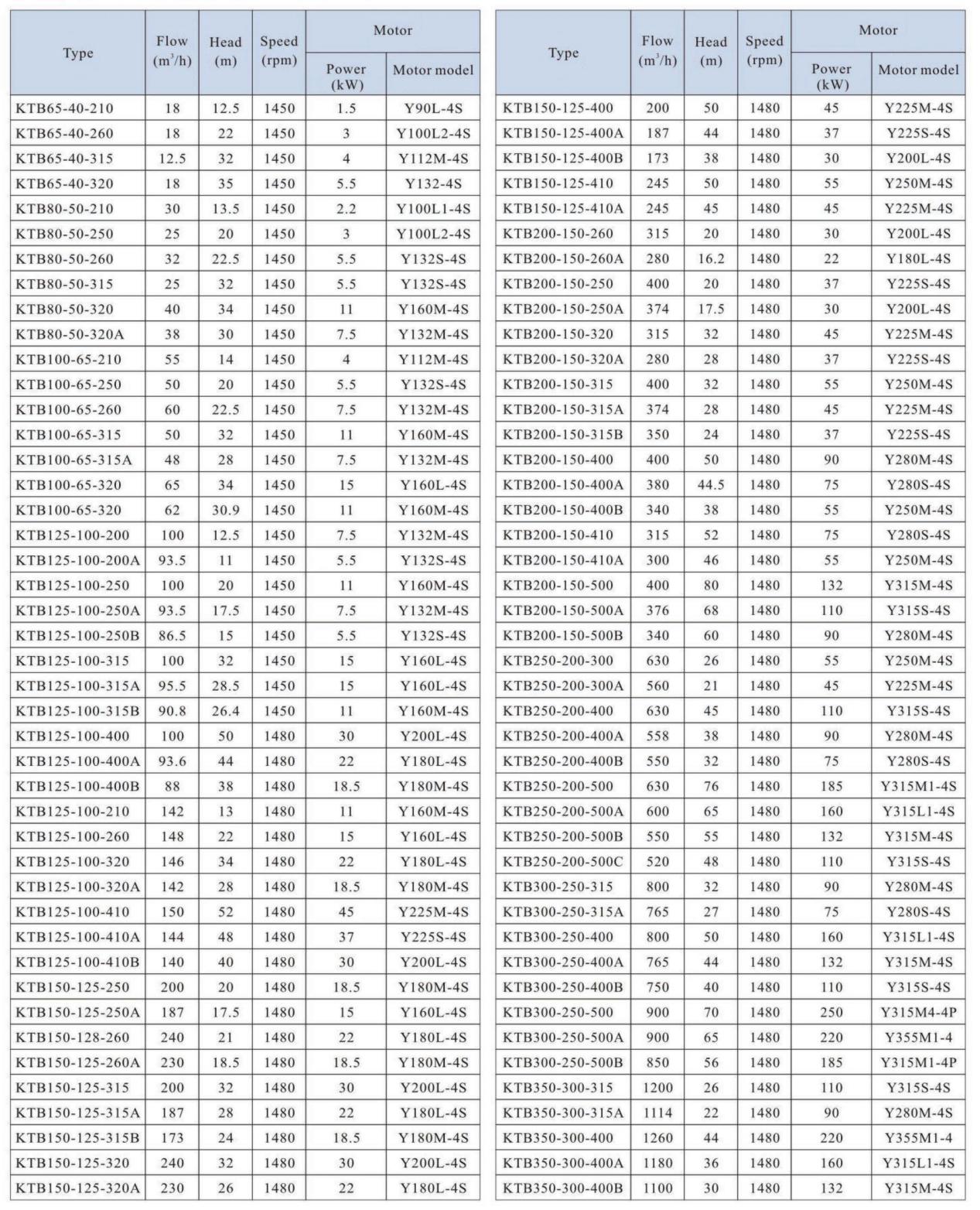

Performance Parameter

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for Cast Iron Stainless Steel Centrifugal Water Pump Manufacturer – KTB Refrigeration Air-Conditioner Pump – State Machinery Equipment Manufacturing , The product will supply to all over the world, such as: Bangalore, Bhutan, Manchester, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.