FY Series Corrosion Resistant Submerged Pump

Product features

1.The pump is a vertical submerged pump with beautiful appearance. It is directly installed on the reservoir of the conveyed medium without additional floor space, thus reducing the investment in infrastructure

2.The mechanical seal is cancelled, which solves the trouble of frequent maintenance of other submerged pumps due to the easy wear and tear of the mechanical seal, saves the operating cost of the pump and improves the work efficiency

3.A unique centrifugal double-balanced impeller is used for conveying clean media without solid particles, with extremely low vibration noise and high efficiency; an open double-balanced impeller is used for conveying unclean liquids with solid particles and short fibers. Smooth operation and no blockage

4.The new type of submersible pump can transport light materials such as flammable and explosive, and has almost no wear and low energy consumption due to the improvement in design

5.Its internal structure is made of special materials. There is a gap about the thickness of a piece of A4 paper between the stator and the rotor. The material flows through the middle, which has two functions: one is to cool the motor, so as to ensure the life of the motor. 2. The liquid flows through the gap between the stator and the rotor, which has a good lubricating effect on the bearing. The problem of the temperature rise of the motor [4] and the wear of the bearing have been effectively solved.

Type Designation

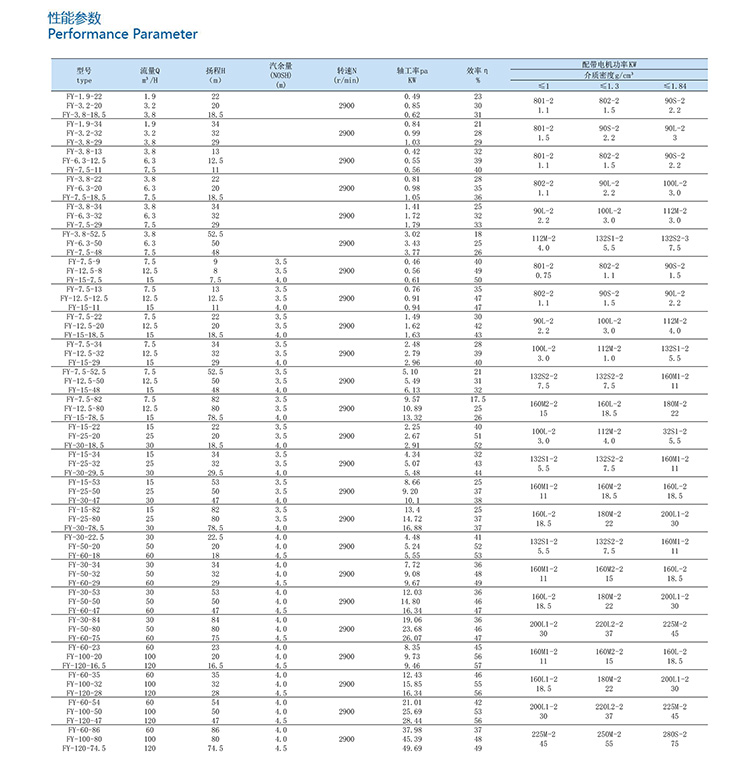

Performance Parameter