QW, WQ, GW, LW, WL, YW Non-Clogging Sewage Pump

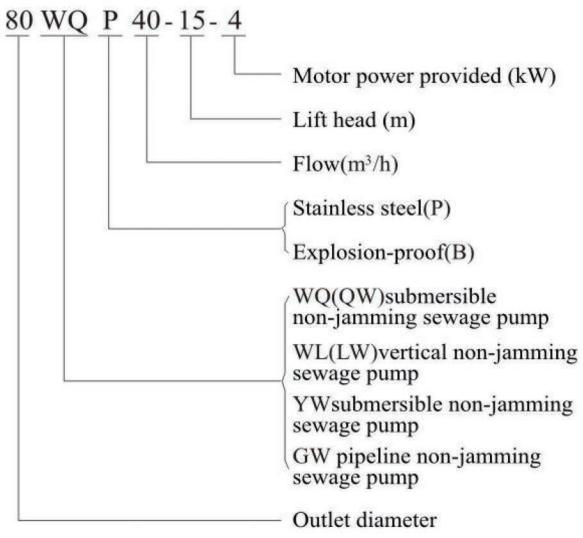

Type Designation

Product Characteristics

1. It adopts the unique single/double-blade impeller structure,which can allow the effective passing of fiber matters with a diameter being 5 times of the pump diameter and also solid particles with a diameter being about 50% of the pump diameter,thus improving the traffic ability of filth greatly.

2. Its mechanical seal adopts the material of new hard corrosion-resistant titanized tungsten so that the pump can achieve over 8,000 hours of continuous safe operation.

3. It boasts a compact and integrated structure, low noise, a noticeable energy-saving effect and being easy for overhaul without building up a pump room because it can be directly submerged to work, thus reducing the project cost greatly.

4. The inside of its seal oil chamber is provided with a high-precision anti-jamming sensor for water leakage detection and the thermal elements are buried inside the stator winding in advance for the automatic protection for the water pump motor.

5. A fully automatic control cabinet is optional in accordance with user needs for the automatic protection of the pump from water leakage, creepage, overload, over temperature and soon, thus improving the safety and reliability of the product,

6. The floating ball switch can control the pump to start and stop automatically in accordance with the required change of liquid level, thus unnecessary for specific personnel in charge and very easy for use.

7. WQ series is provided with an optional double-guide automatic coupling installation system in accordance with user needs, which facilitates the installation and maintenance greatly, so people needn’t pass in and out of the sump.

8. It is available for use within the total head, thus ensuring to keep the motor from overload.

9. It is available for two different installation modes: fixed automatic coupling and removable free installation systems.

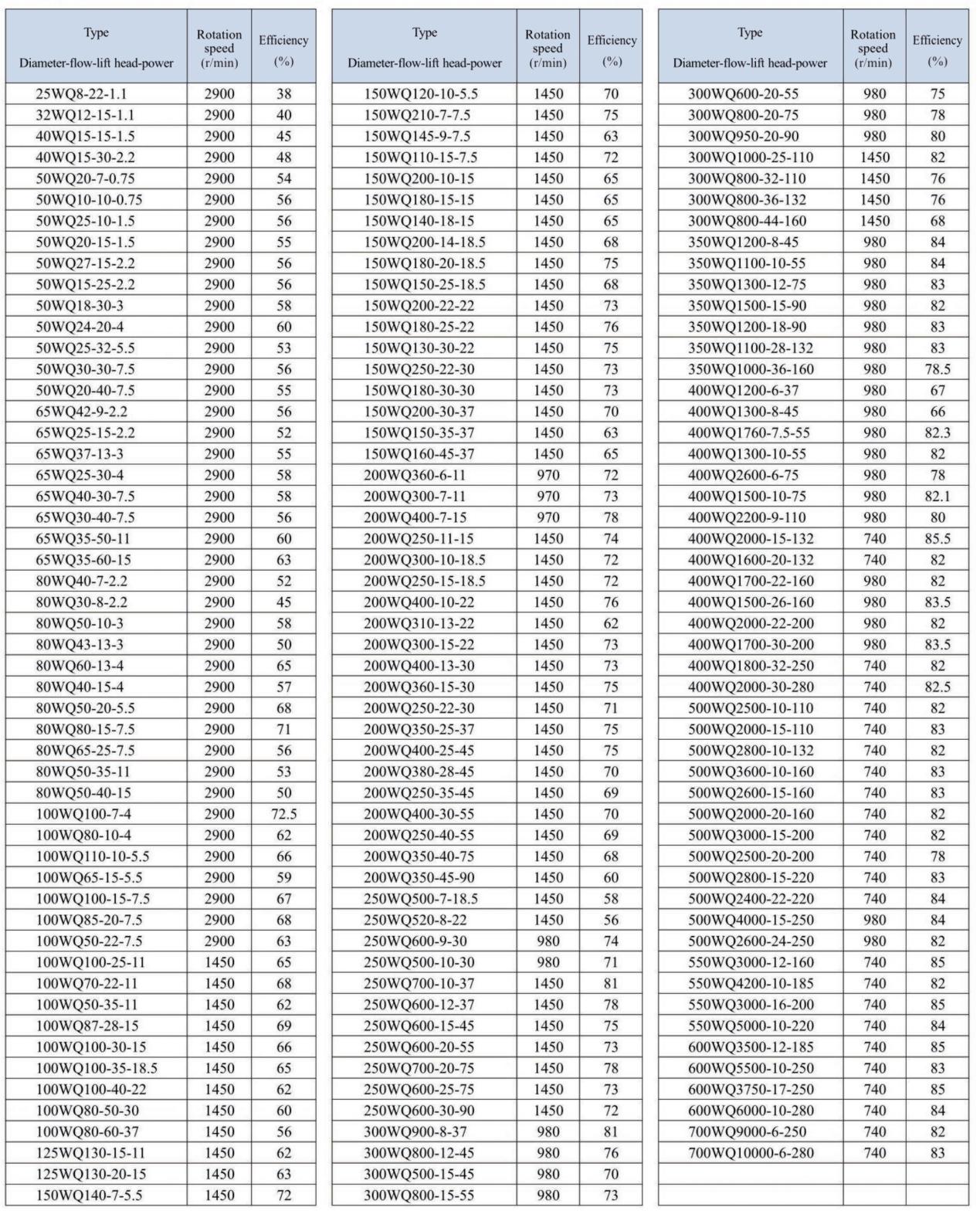

Performance Parameter