S, SH Single-Stage Double-Suction Centrifugal Pump

Features

The suction port and discharge port of this type of pump are below the axis line of the pump, and the axis is perpendicular to the horizontal direction. There is no need to disassemble the inlet and outlet water pipes and the motor during maintenance. Viewed from the direction of rotation, the pump rotates clockwise/according to the user If necessary, it can also be changed to rotate counterclockwise.

The main parts of the pump are: pump body, pump cover, impeller, shaft, double suction sealing ring, shaft sleeve, etc.

The pump body and the pump cover constitute the working chamber of the impeller, and the pipe screw holes for installing the vacuum gauge and the pressure gauge are made on the inlet and outlet flanges. The lower part of the water inlet and outlet flanges is provided with pipe screw holes for water discharge.

The impeller that has been checked for static balance is fixed on the shaft with the bushing nuts on both sides of the bushing, and its axial position can be adjusted by the bushing nuts.

The pump shaft is supported by two single row radial ball bearings. The bearings are installed in the bearing body, installed at both ends of the pump body, and lubricated with butter.

The double suction sealing ring is used to reduce the leakage of water from the pressure chamber of the pump back to the suction chamber.

The pump is directly driven by the electric motor through the elastic coupling. If necessary, it can also be driven by an internal combustion engine.

The shaft seal is a soft packing seal, and a mechanical seal structure can be used according to user needs.

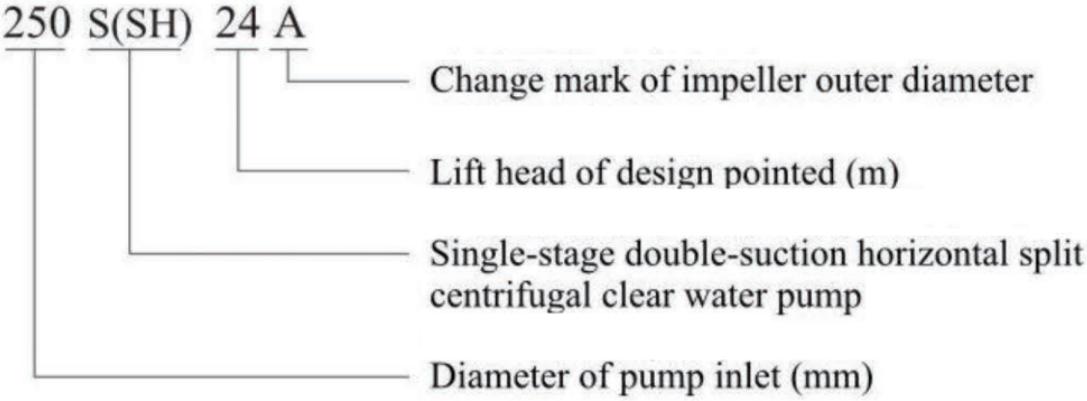

Type Designation

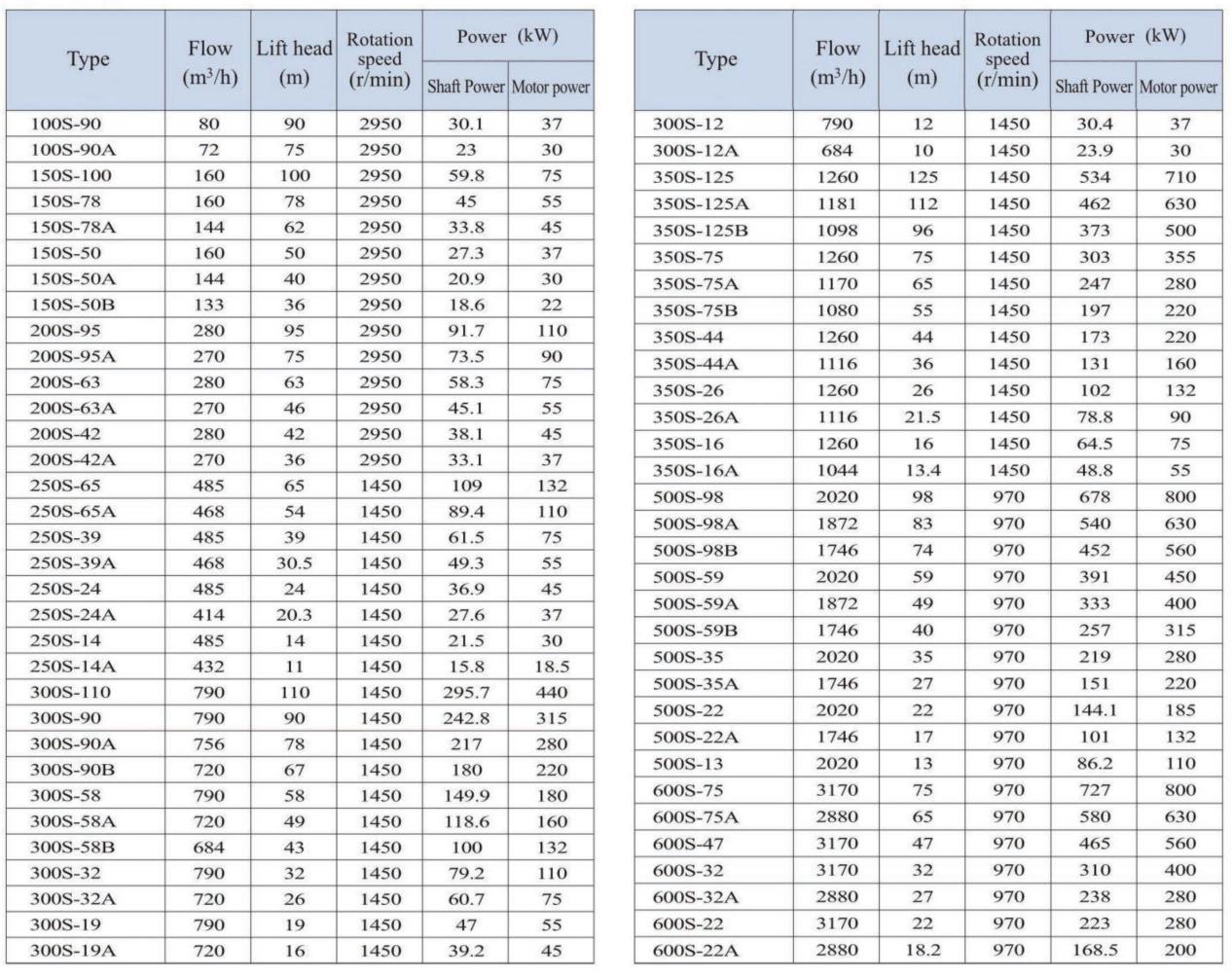

Performance Parameter