Single Seal Chocolate Pump Factory – GLFC Stainless Steel Magnetic Pump – State Machinery Equipment Manufacturing

Single Seal Chocolate Pump Factory – GLFC Stainless Steel Magnetic Pump – State Machinery Equipment Manufacturing Detail:

Product Features

Magnetic pump (also known as magnetic drive pump) is mainly composed of pump head, magnetic drive (magnetic cylinder), motor, base and other parts. The magnetic drive of the magnetic pump is composed of an outer magnetic rotor, an inner magnetic rotor and a non-magnetic isolation sleeve. When the motor drives the outer magnetic rotor to rotate through the coupling, the magnetic field can penetrate the air gap and the non-magnetic material isolation sleeve, and drive the inner magnetic rotor connected to the impeller to rotate synchronously, realizing the non-contact synchronous transmission of power, which will easily leak. The dynamic sealing structure is transformed into a static sealing structure with zero leakage. Since the pump shaft and the inner magnetic rotor are completely closed by the pump body and the isolation sleeve, the problems of “running, running, dripping and leaking” are completely solved.The medium contact part is made of stainless steel, which has good corrosion resistance to organic acids, organic compounds, alkalis, neutral solutions and various gases. The double spiral groove carbon right ink bearing has strong wear resistance, ensuring that Long product life, ideal for leak-free transport of corrosive media.

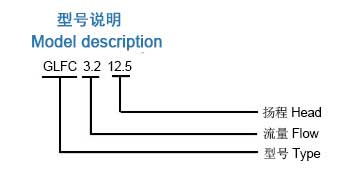

Type Designation

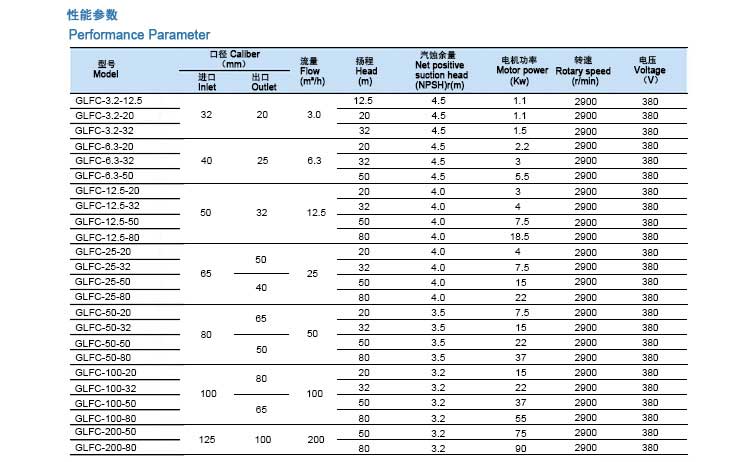

Performance Parameter

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for Single Seal Chocolate Pump Factory – GLFC Stainless Steel Magnetic Pump – State Machinery Equipment Manufacturing , The product will supply to all over the world, such as: Ecuador, Armenia, Miami, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.